Multipurpose Grease Innovations: Increasing Performance While Lowering your Carbon Footprint with Lithium-Free Grease

In today’s climate, where supply chain challenges and sustainability demands shape every industry, the lubrication sector is no exception. With the increased usage of lithium for batteries, electric car manufacturers are driving demand and higher prices across multiple segments. Leaving the grease industry searching for alternatives.

Anhydrous Calcium (ANH CA) grease has emerged as a cutting-edge alternative to traditional lithium-based greases. This innovation offers a modern solution to the limitations of traditional lithium-based greases. If you’re still relying on lithium-based greases, it’s time to rethink your strategy.

Let’s explore why ANH CA greases are the better choice— and not just for your operations.

Lithium Grease VS the Rise of EV Batteries

For decades, lithium-based greases were the go-to solution. Their versatility and balanced performance made them a staple across industries. However, the increasing demand for lithium in electric vehicle (EV) batteries has created significant supply chain pressures. Since 2023, global lithium grease production has dropped by 16%, with prices soaring as a result. (Sources: Lubes'n'Greases, F&L Asia, July 30, 2024).

In response, calcium-based greases have stepped up, particularly in Europe, where their production share increased from 15% in 2021 to 18% in 2022. (Sources: Lubes'N'Greases, F&L Asia) Anhydrous Calcium greases have proven to be not just an alternative, but a premium upgrade. They excel where lithium grease falls short, offering advantages in performance, sustainability, and availability.

Sources:

1/ Lithium Thickeners Dip in Europe - Lubes'N'Greases (lubesngreases.com)

2/ Decline in participation impacts NLGI grease production survey - F&L Asia (fuelsandlubes.com)

What Is Anhydrous Calcium (ANH CA)?

At its core, Anhydrous Calcium is a water-free thickener technology that forms the foundation of a high-performance grease. Its unique structure delivers exceptional resilience and reliability in challenging environments where water resistance, low-temperature performance, and mechanical stability are critical. ANH CA greases are the premium candidates to succeed a lithium-containing grease portfolio.

Originally developed for cold and wet applications, ANH CA greases are now widely used across segments, making them ideal multipurpose greases.

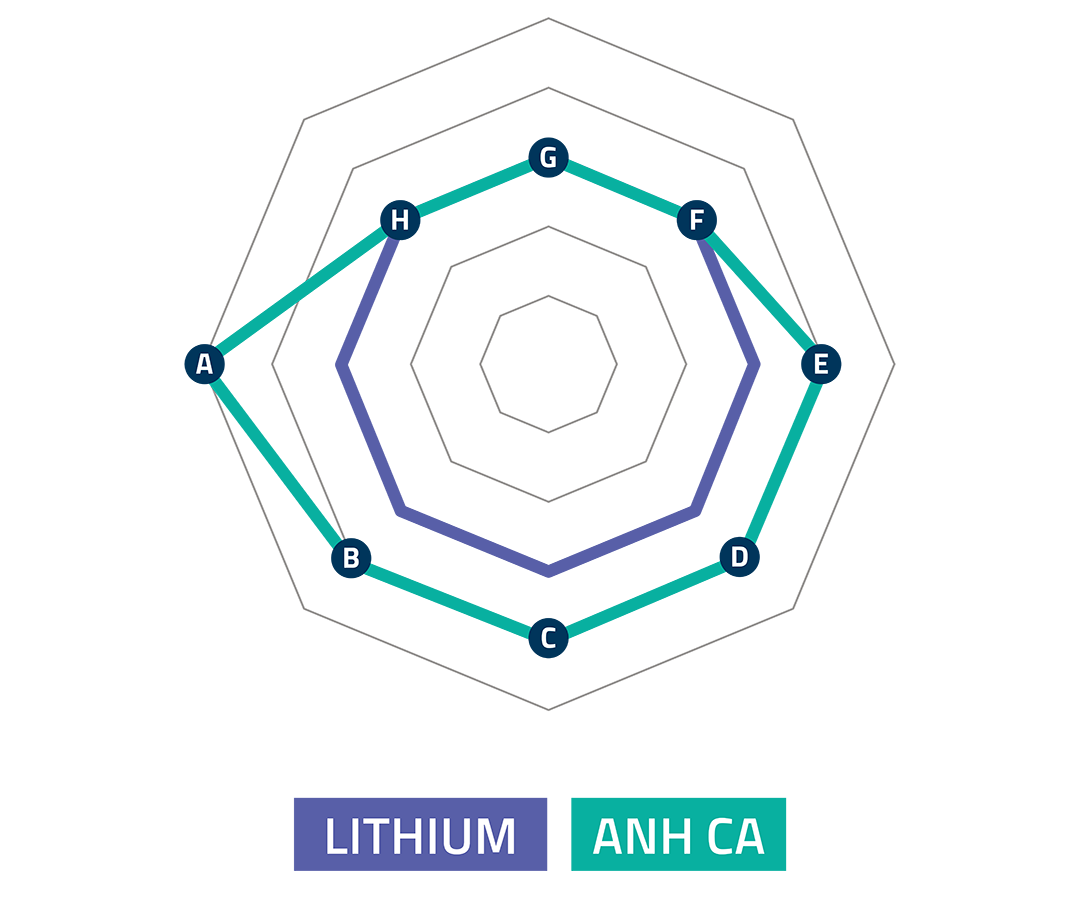

How ANH CA Greases Outperform Lithium-Based Greases

The real measure of any grease lies in its performance. Here’s how ANH CA grease excels in comparison to traditional lithium-based grease:

1. Technical Performance: What’s Under the Hood?

ANH CA greases thrive in environments exposed to moisture, extreme temperatures, and high mechanical stress. This makes them ideal for applications like: Wheel Hubs, Roller Bearings, Plain Bearings, Chassis Components, Fifth Wheel (Pivot Pin), Crane (Slew Ring), Wire Ropes, Chainsaws...

ANH CA OUTPERFORMS LITHIUM | A) WATER RESISTANCE: Superior ability to lubricate in the presence of water. B) LOAD CAPACITY: Standard grease technologies rely on additives to resist high loads. Increased performance can be obtained by inclusion of extreme pressure additives and/or solid lubricants. C) MULTI-PURPOSE: Broad applicability across all segments. D) THERMAL STABILITY: The upper temperature limit for ANH CA greases is 120 degrees °C. Which is equivalent to a high-quality lithium-based grease. E) ISOLATION: Well-suited to sealing off fluids, dust and debris from the application due to its ability to handle ingress of moderate amounts of water without losing its consistency or ability to lubricate. |

ANH CA PERFORMS EQUAL TO LITHIUM | F) LOW TEMPERATURES: Exceptionally low temperature properties especially in combination with polymer-enhanced base oils. Compared to lithium greases at lower temperatures, ANH CA greases are less elastic and have a shorter relaxation period, making it easier to pump. G) SHEAR STABILITY: The structural strength of ANH CA thickener displays better resistance to shear and mechanical degradation more generally when compared to lithium. H) ADHESION ANH CA: greases generally offer better adhesion, particularly in challenging conditions involving moisture. This makes them particularly suitable for applications where strong adhesion and water resistance are essential. |

2. Environmental Benefits of ANH CA Greases

Sustainability is no longer optional—it’s a necessity. ANH CA greases offer significant environmental advantages over lithium greases, making them a forward-thinking choice for businesses aiming to minimise their ecological footprint. By transitioning to ANH CA greases, industries can achieve operational excellence while meeting sustainability goals.

Lower Carbon Footprint

10x less CO₂ released during raw material extraction. 14% lower emissions during manufacturing.

Reduced Resource Use

100x less water and 20x less energy consumption compared to lithium.

Low Toxicity

Safer for workers, equipment, and the planet. ANH CA greases have a minimal risk profile during handling and manufacturing.

Higher Biodegradability

Their eco-friendly composition means less environmental impact, especially in applications where grease is expelled or lost.

3. Availability: A Stable Solution

Lithium supply volatility is a growing concern across industries. As battery production accelerates, the pressure on lithium resources will only increase. ANH CA greases, on the other hand, are readily available, reducing supply risks and improving cost stability.

Sources

1/ Can Calcium Limit Lithium reLiance? - Axel Christernsson

2/ Decline in participation impacts NLGI grease production survey - F&L Asia (fuelsandlubes.com)

3/ Shift in lubricating grease industry: Beyond lithium greases - F&L Asia (fuelsandlubes.com)

ANH CA GREASE EP 2

At the heart of our range is ANH CA GREASE EP 2, a performant multi-purpose, cross-segment grease that delivers several improved performance properties compared to Lithium-based alternatives.

Key Applications:

- Medium-loaded ball bearings in wet or corrosive environments.

- Multi-purpose applications across industries, from manufacturing to agriculture.

Performance metrics where ANH CA outperforms lithium greases:

| ✔ Exceptional water resistance | ✔ Outstanding shear stability |

| ✔ Superior adhesion | ✔ High biodegradability |

| ✔ Low-temperature lubricity | ✔ Low toxicity |

Applications That Demand ANH CA Performance

Anhydrous Calcium greases are built for versatility. Their superior performance characteristics make them ideal for a range of applications, including:

- Central lubrication systems

- Plain and roller bearings

- Ball bearings in wet and corrosive environments

- Industrial machinery exposed to extreme conditions

Wolf Lubricants’ Multipurpose Grease Innovation

Our updated grease portfolio reflects a commitment to both technological innovation and sustainability. By choosing ANH CA, you’re contributing to a cleaner, greener future, while improving operational efficiency and increasing performance.

Discover our comprehensive grease range and experience performance without compromise.