The basics of lubricants: base oils. (1/9)

Learn everything about lubricants with ‘the basics of lubricants’: a series of nine articles, with each article covering in-depth insights about what everyone should know about lubricants.

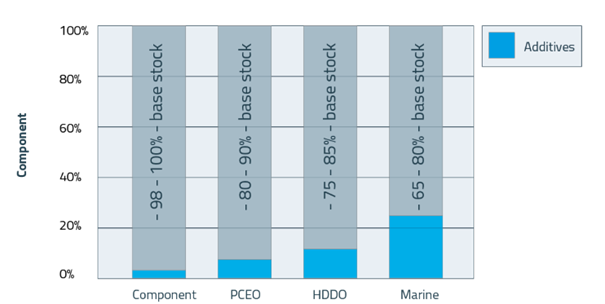

When talking about the basics of lubricants, base oils (or base stocks) are the logical starting point. Counting for 70-95% of a lubricant’s composition, these oils are therefore considered as its main component.

Base oils cannot be found in nature, but are refined from crude oil. In general, about 2% of all crude oil produced in the world is used for the fabrication of lubricants. To get from crude oil to base oils, there are however a few steps to take.

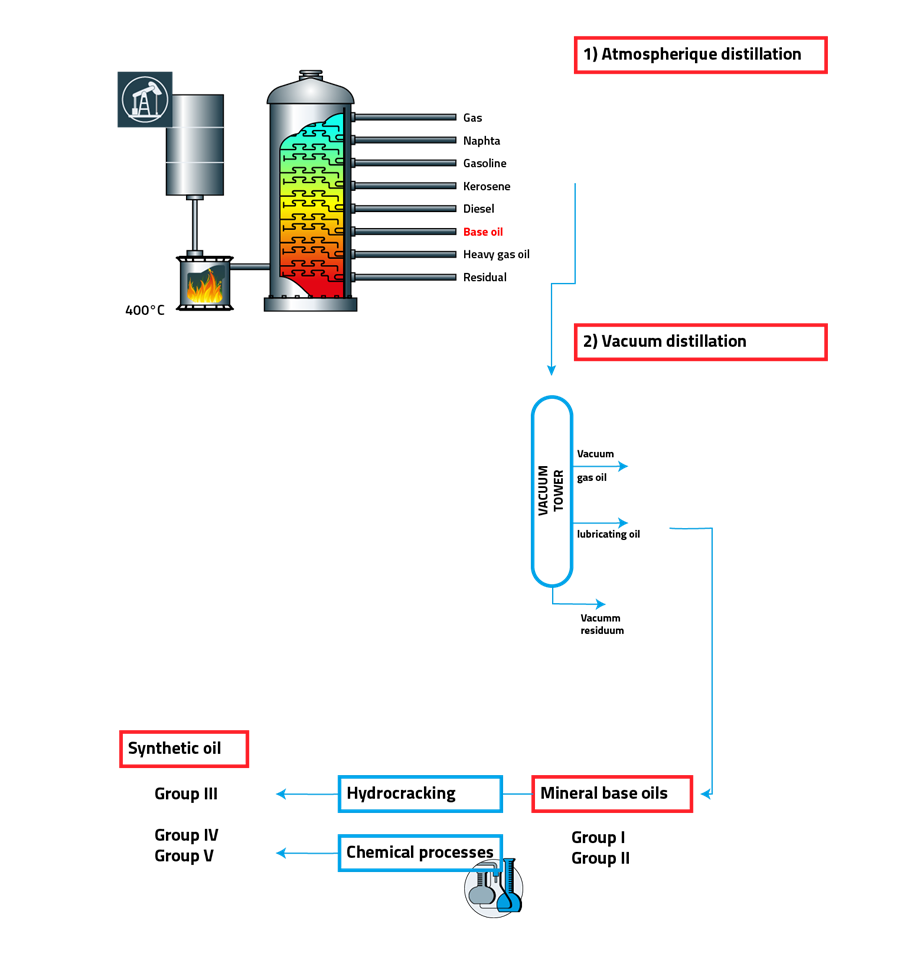

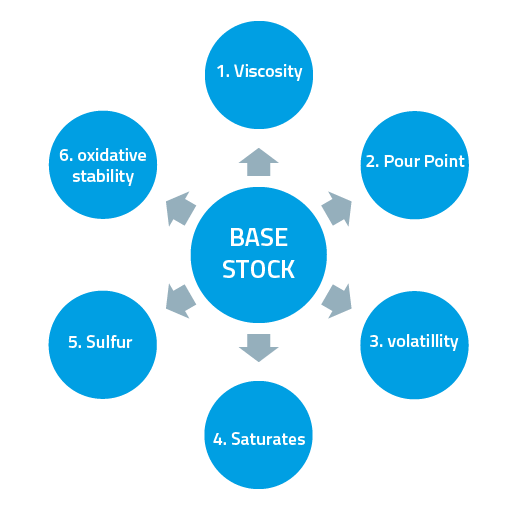

To start, crude oil goes through two distillation processes: Atmospheric and vacuum distillation. After the second distillation, base oils go through a thorough analysis to make sure they have the right test results on important characteristics. Viscosity, volatility and oxidation stability are a few examples of key base oil features. Eventually we have base oils that are ready for the process of blending with additives. This will be discussed in the next chapter.

Distillation is the process of physically separating substances, like liquids and vapours, accelerated by high temperatures. At atmospheric distillation, crude oil is heated up to a temperature of about 400°C. The heat accelerates the diffusion of crude oil into a separation of liquids and vapours in the distillation tower. As liquid is heavier in weight, it stays more down the bottom of the tower while the vapours rise more to the top.

A few fractions can be refined from heated crude oil and are even ready for use (e.g. gases), but only base oils go through a second distillation. The second distillation process takes place in a vacuum setting, enabling to obtain distillates with high boiling points on lower temperatures with, eventually, base oils as the end-product.

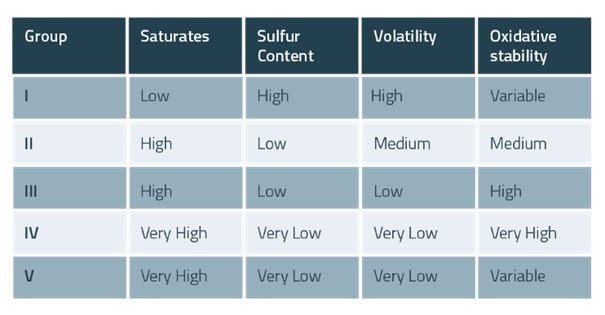

Base oils can be segmented into 2 main groups, according to the used treatments:

- Mineral base oils, group I and II, are base oils refined from crude oil

- Synthetic base oils, group III, which are mineral base oils refined through hydrocracking*, and group IV and V, which are oils purely generated by synthetic or chemical processes

*Hydrocracking mineral base oils means cracking heavy, high-sulfur molecules of the oils into better quality, low-sulfur molecules under high temperature and pressure.

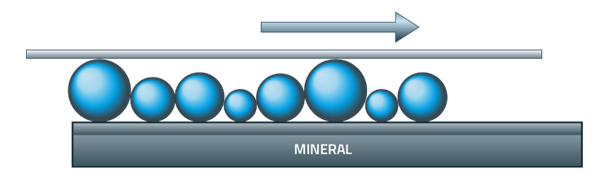

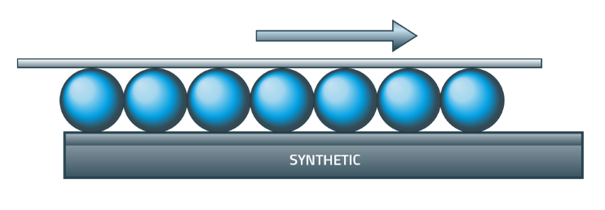

Synthetic base oils are generated by certain chemical processes that make them perform better thanks to their consistent molecular structure and purity. Because of the consistent size and shape of the molecules and the adherence between them, there will be less friction between the metal surfaces and a significant overall better performance.

Base oils vary in effect on engine performance. Adding additives enhances these effects and adds additional beneficial features to the lubricant. The amount of additives varies from segment to segment:

However, before adding any additives, a thorough analysis of all base oil characteristics is conducted. A few important characteristics are:

With the earlier mentioned base oil groups (I-V) and after the oil analysis, a comparison between all base oils is now easy to make.

There is a general trend, mostly driven by environmental norms and specifications, towards better quality synthetic base oils. Technical evolutions of the past decade brought engine designs that require more sophisticated oil formulations. In the past, you could use mineral base oils for basically every type of engine, but the newest engine designs no longer support this type of oil.

At Wolf, we mostly work with synthetic base oils as they show a significantly better performance on all characteristics. This counts also for mineral base oils that went through a chemical refinery process (hydrocracking), like synthetic Group III base oils.

The benefits of synthetic base oils:

- Improved fuel economy and power output

- More resistant to temperature fluctuations and oxidation processes

- Cleaner engine surfaces

- Superior wear control

- Increased drain interval to the finished lubricant

However, some vehicles still work perfectly with mineral base oils. What matters most is to know about the differences in oil and to make sure you use the right lubricant for your specific vehicle. Use our online recommendation tool to find out which oil fits your vehicle needs.

In short:

- Base oils can be refined from crude oil or generated by chemical processes

- There are 2 types of base oils: Mineral and synthetic base oils

- There a number of important characteristics to consider when deciding on base oils, like viscosity and oxidation stability

- In the future, the demand for synthetic base oils will increase

For more explanation about these lubricant terms, download our whitepaper with 51 lubricant related terms.